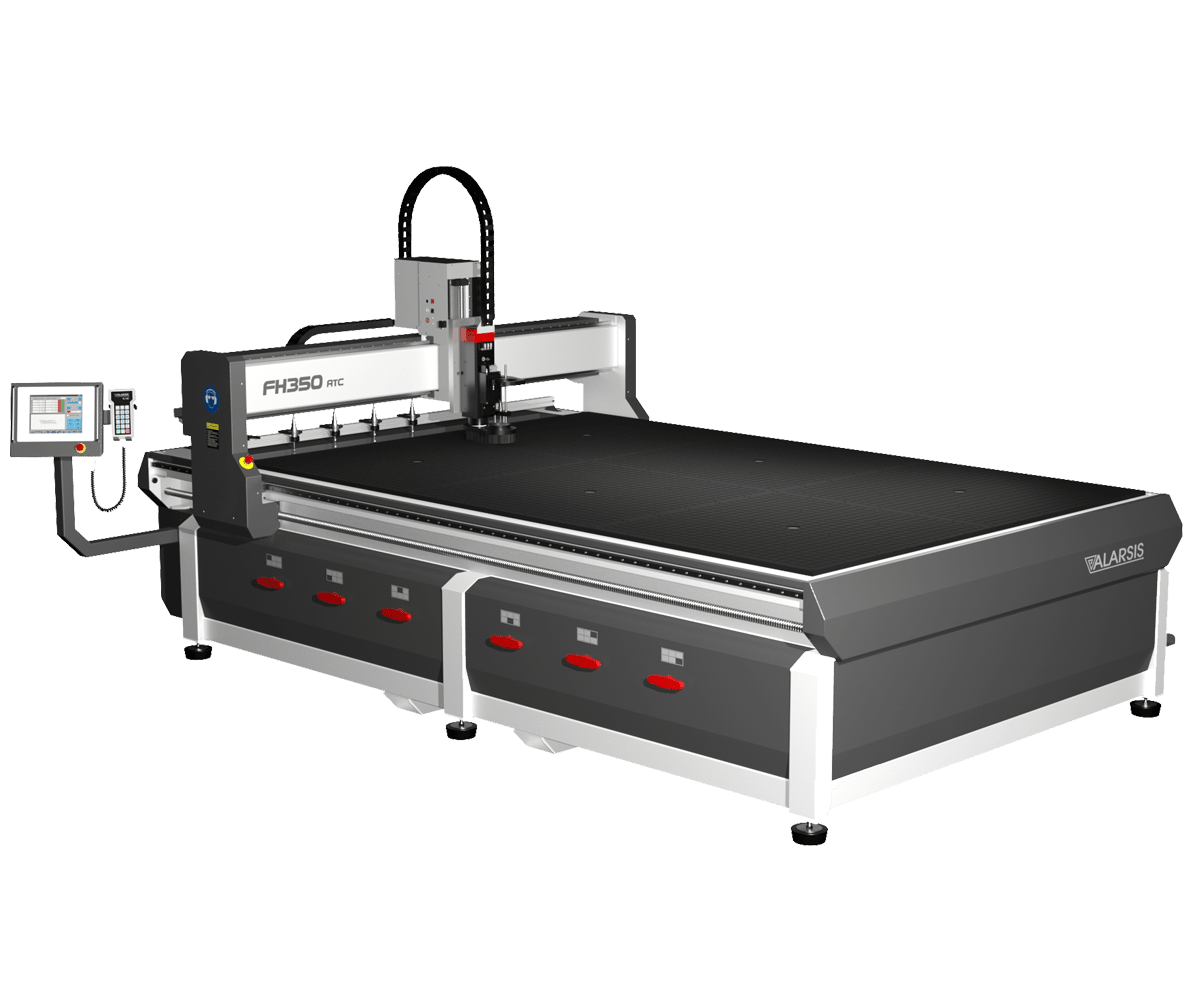

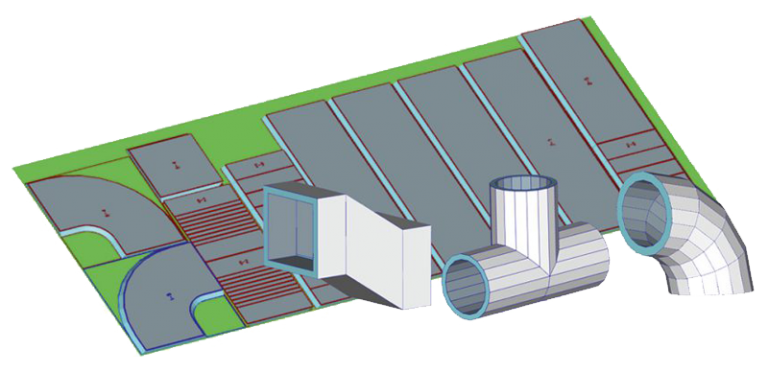

Production model for machining where both power and precision performance are required with high workloads. Ideal for the carpentry and sign industry, with tubular steel chassis, very robust and low maintenance, characteristics of the entire FH series. Useful working area of 305x202cm and height of 150mm.

Provides unrivalled power and precision.

- Welded tubular steel frame.

- Vacuum table with 6 sectors and 7CV pump.

- Electronics with RTA drivers and class 6 robotics wiring.

- TEXCOMPUTER touch screen controller.

- Linear guides with self-lubricating, sealed and backlash-free recirculating ball bearing slides.

- Spindle transmission on all axes, with preloaded recirculating ball nuts and 70Kg/cm torque SanyoDenky servo motors.

- Travelling speed 20 metres/min.

- Adjustable resolution 0,001mm.

- Chip suction system.

- 5hp ELTE milling motor, 6000~24000rpm. 7hp in option.

- Probe for Z-axis zero setting.

- Laser pointer for X,Y axis zero setting verification.

- Working dimensions 3050x2020mm.

- Useful height Z bridge 150mm.