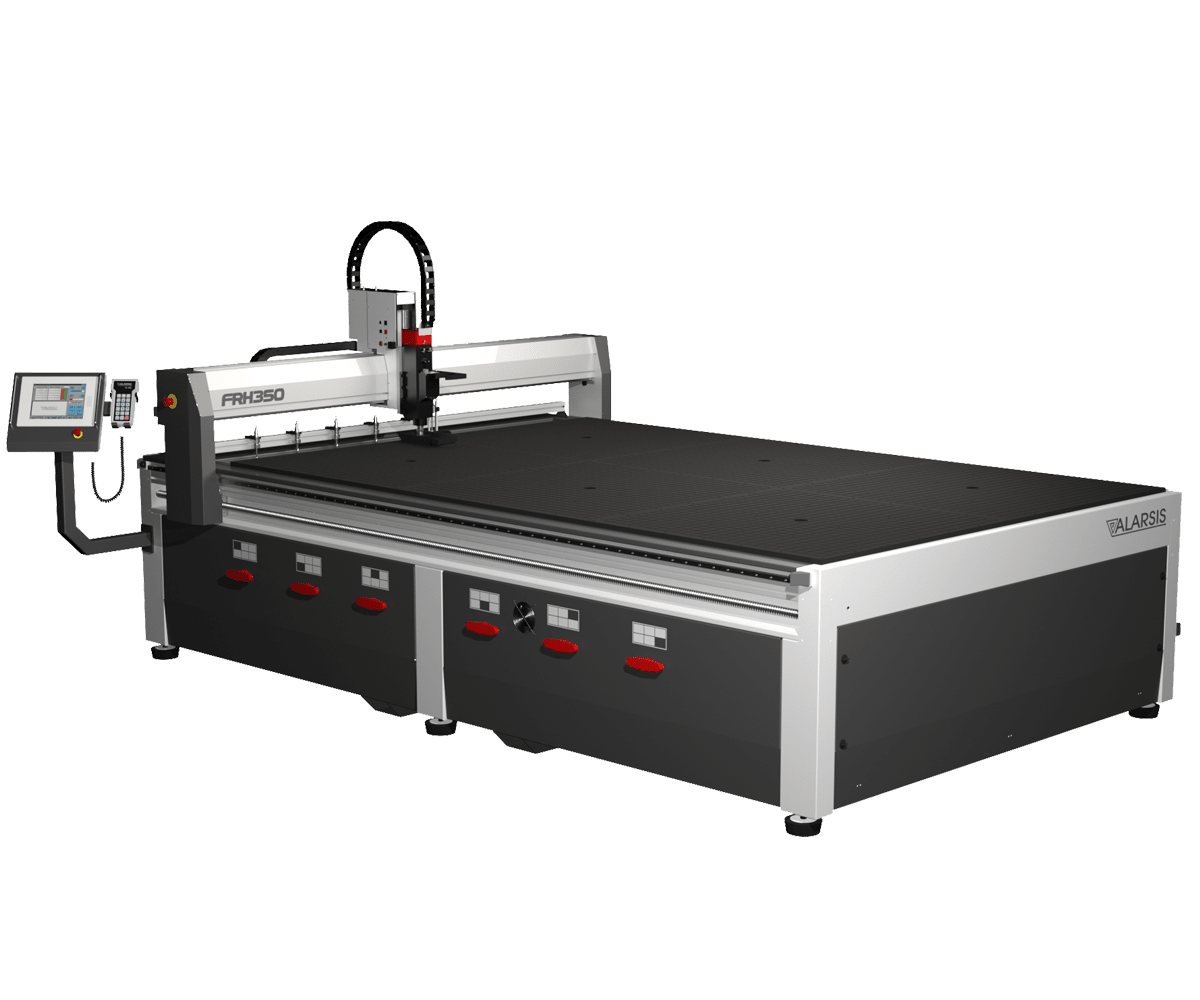

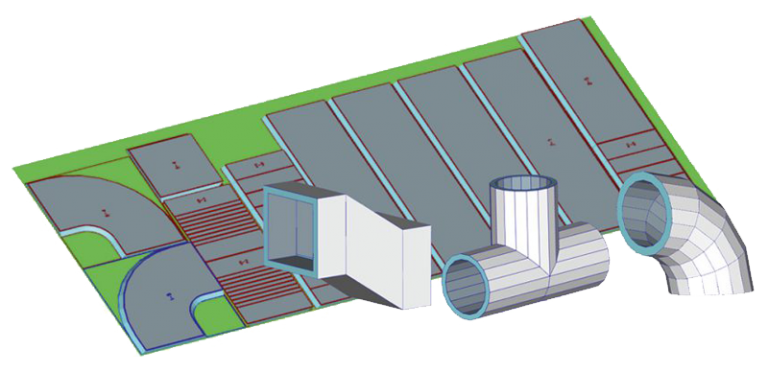

Production model for machining where both power and precision performance are required. Aimed at the large format graphic arts sector. Very robust and low maintenance, characteristics of all the FRH series. With optional automatic tool changer. Useful working area of 300 x 200 cm and height of 120mm. Ball screw drive on ALL AXES for unrivalled power and precision.

- Steel frame.

- Sectored vacuum table with 7CV pump.

- Electronics with RTA drivers and class 6 robotics wiring.

- Tex Computer touch screen CNC control system.

- Linear guides with self-lubricating, sealed and backlash-free recirculating ball bearing slides.

- Spindle drive on all axes, with preloaded recirculating ball nuts and 30Kg/cm PaP motors. Servos in option.

- Travelling speed 20 metres/min.

- Resolution 0,005mm.

- Chip suction system.

- 3 HP brushless spindle, 6000~24000rpm, air or water cooled.

- Probe for Z-axis zero setting.

- Laser pointer for X,Y axis zero setting verification.

- Automatic tool change in option.

- Useful working dimensions 3050 x 2020 mm.

- Working height of Z-bridge 120 mm.

- Machine dimensions 3850 x 2350 mm.

- ATC, MTC

Brushless motor heads for milling work with or without tool change.